Understanding the Role of Steel Slabs in Manufacturing

Understanding the Role of Steel Slabs in Manufacturing

Steel slabs are fundamental to the steel manufacturing process, acting as a critical intermediate product in the production of various steel forms and grades. From hot-rolled coils to plates, beams, and sheets, steel slabs serve as the foundation for the manufacturing of a vast array of steel products used in industries such as construction, automotive, shipbuilding, and machinery. This blog explores the significance of steel slabs, their production process, and their applications in different industries.

What Are Steel Slabs?

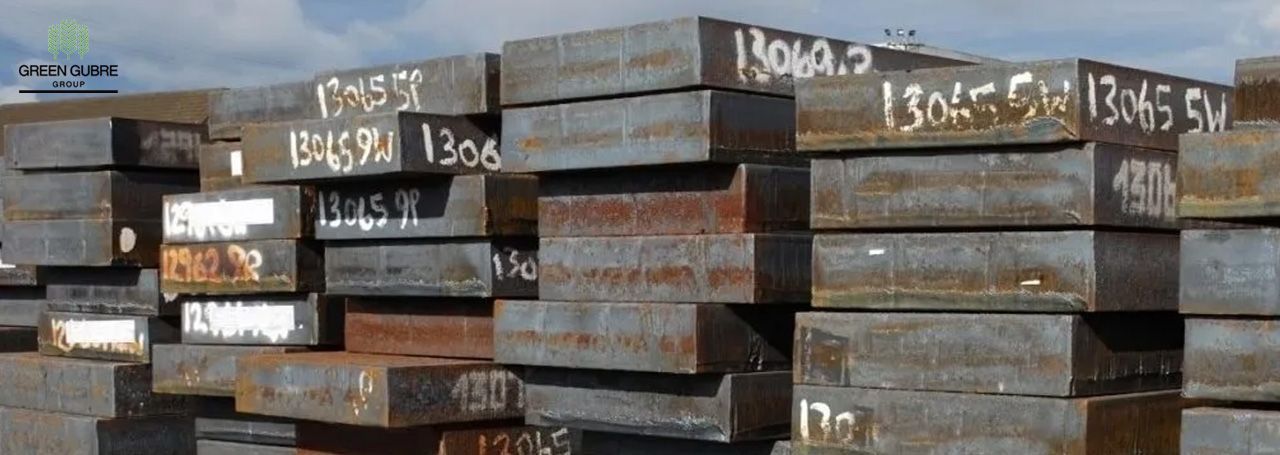

Steel slabs are semi-finished steel products that are rectangular and produced through continuous casting. These slabs are made by solidifying molten steel into a form that can be further processed into other shapes and sizes. The slabs are then rolled or formed into different types of steel products, including sheets, plates, coils, and structural components. Steel slabs are known for their durability, strength, and versatility, making them a cornerstone of modern manufacturing.

Production Process of Steel Slabs:

1. Molten Steel Production:

Steel slabs are produced by melting iron ore in a blast furnace or recycling scrap steel in an electric arc furnace. The molten steel is then poured into a casting mold, where it is solidified into large, rectangular slabs.

2. Continuous Casting:

The continuous casting process is used to produce steel slabs of uniform size and quality. During this process, molten steel is fed into a casting machine that molds the steel into long, continuous slabs. These slabs are then cut into desired lengths, ensuring consistency in size and thickness.

3. Rolling and Forming:

After casting, steel slabs are reheated and passed through a rolling mill, where they are shaped and reduced in thickness to create specific steel products. The rolling process can produce hot-rolled or cold-rolled products, depending on the intended application.

Key Benefits of

Steel Slabs:

1. Versatility in Steel Production:

Steel slabs are used to manufacture a wide variety of steel products, including sheets, plates, coils, and structural components. This versatility allows manufacturers to produce steel in different sizes and grades, meeting the needs of diverse industries.

2. High Strength and Durability:

Steel slabs provide a strong and durable foundation for various steel products. Their structural integrity makes them suitable for heavy-duty applications, such as construction materials, shipbuilding, and automotive manufacturing.

3. Efficiency in Production:

The continuous casting process used to create steel slabs ensures that the production of steel is efficient and consistent. This process reduces waste, improves product quality, and lowers production costs, making steel slabs a cost-effective choice for manufacturers.

4. Customizability:

Steel slabs can be produced in various sizes, thicknesses, and compositions to meet the specific requirements of different industries. This customizability ensures that manufacturers can produce steel products that are tailored to their needs.

Applications of

Steel Slabs:

1. Hot-Rolled Coils and Plates:

Steel slabs are often used to produce hot-rolled coils and plates, which are essential in the manufacturing of automotive parts, machinery, and structural components. Hot-rolled steel is known for its strength and durability, making it ideal for heavy-duty applications.

2. Cold-Rolled Steel:

Steel slabs are also used to produce cold-rolled steel, which is characterized by its smooth surface and precision in thickness. Cold-rolled steel is commonly used in the production of appliances, electronics, and furniture, where a high-quality finish is required.

3. Structural Steel Components:

Steel slabs are rolled into beams, channels, and angles used in construction and infrastructure projects. These structural steel components provide the necessary strength and support for buildings, bridges, and other large-scale structures.

4. Shipbuilding and Heavy Machinery:

In shipbuilding and heavy machinery manufacturing, steel slabs are transformed into thick plates and structural components that require exceptional durability and strength. Steel slabs are critical in these industries due to their ability to withstand heavy loads and harsh conditions.

5. Automotive Industry:

The automotive industry relies on steel slabs to produce parts such as frames, chassis, and body panels. The high strength-to-weight ratio of steel makes it an ideal material for ensuring vehicle safety and performance.

Environmental Impact of

Steel Slabs:

The steel industry has made significant strides in reducing the environmental impact of steel production, including the production of steel slabs. Many steel manufacturers are adopting sustainable practices, such as using recycled scrap steel in electric arc furnaces and reducing energy consumption during the casting and rolling processes. Steel slabs made from recycled materials help lower the industry’s carbon footprint, contributing to more eco-friendly manufacturing practices.

Global Demand for

Steel Slabs:

The global demand for steel slabs is driven by the continued growth of industries such as construction, automotive, and infrastructure development. As countries invest in building modern infrastructure and expanding industrial capacities, the demand for high-quality steel products increases. Steel slabs play a critical role in meeting this demand by serving as the raw material for various steel products used in these industries.

Conclusion:

Steel slabs are a fundamental product in the steel manufacturing process, providing the foundation for a wide range of steel products used in industries such as construction, automotive, shipbuilding, and machinery. Their versatility, strength, and efficiency in production make them essential for modern manufacturing. As global demand for steel continues to rise, steel slabs will remain a key component in the production of high-quality steel products. Explore our range of premium steel slabs designed for optimal performance in industrial applications on our dedicated product page.